-

Mail 2561880819@qq.com

-

Contacts +86-18928672668

+86-757-85213502

Mail 2561880819@qq.com

Contacts +86-18928672668

+86-757-85213502

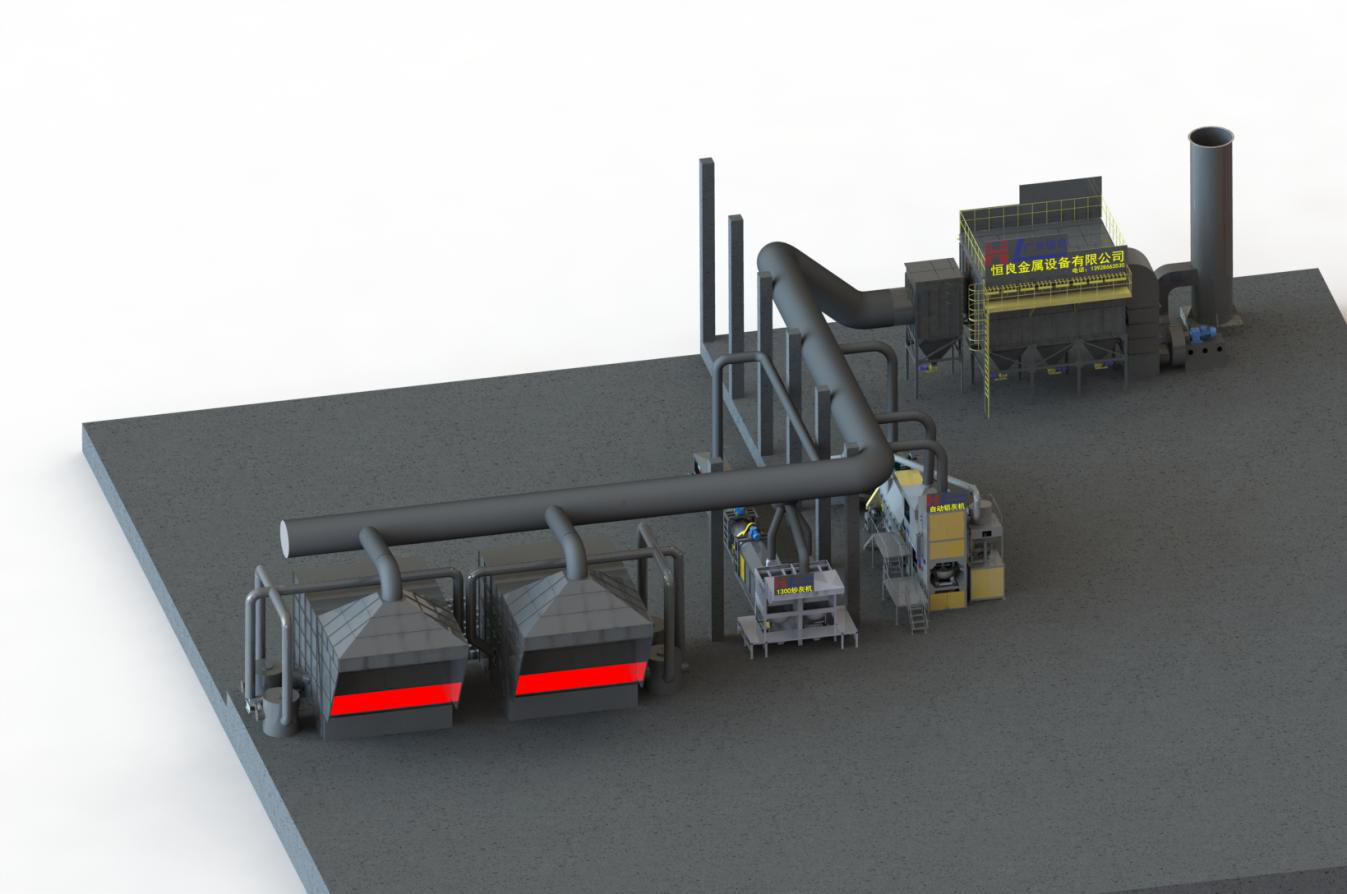

Furnace opens door operation during feeding and slag degassing, flue gas is discharged from the mouth, pressure in the furnace is slightly positive when the door is closed for normal smelting, and the flue gas generated in the furnace is discharged through several small holes in the door or exhaust fan of regenerative energy-saving burner.

Smelter and aluminium ash treatment equipment will produce a large amount of smoke during the working stages of feeding, degassing, slag raking and stir-frying.If the discharge is not handled, it will seriously affect the surrounding environment and harm the health of employees. Therefore, appropriate environmental dust removal equipment must be matched to make the flue gas discharge meet the national discharge requirements after treatment.

The design scope is: air volume design, smoke and dust capture device, dust collector, wind motor matching, smoke exhaust pipe system, electrical control system design.

2. Design Basis

2.1. Regulations on Environmental Protection Design for Metallurgical Industry (YB9066-95)

2.2,'Design Specification for Heating Ventilation and Air Conditioning'(GBJ19-88)

2.3, "Standards for Release of Pollutants from Recycled Copper, Aluminum, Lead and Zinc Industry" (GB 31574-2015)

2.4,'Hygiene Standard for Industrial Enterprise Design'(TJ36-79)

2.5. Actual conditions at various working points

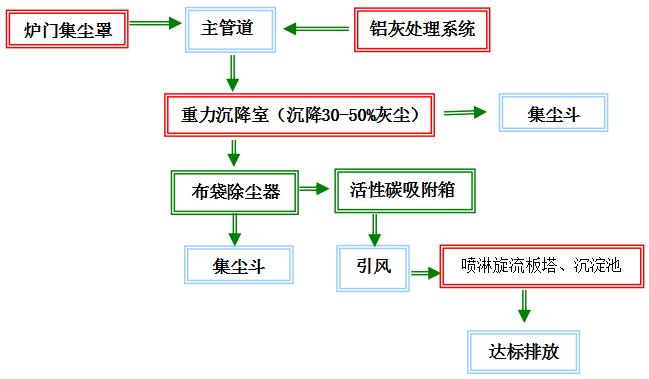

The dust collector system collects the smoke from the furnace (feeding one furnace at a time) and the aluminium dust treatment system, the dust cover at the furnace mouth and the aluminium dust treatment system.Treatment index: discharge concentration < 10mg/Nm3, dust removal efficiency < 99.5%, dust capture rate < 90%, Lingmann blackness < 1 grade.

The process flow is as follows:

Copyright © 2020-2024 Foshan Hengliang Metal Equipment Co., Ltd All Rights Reserved.

粤ICP备20062218号  粤公网安备 44060502002187号

粤公网安备 44060502002187号

Power by: pbinfo.cn

pbinfo.cn

Online

consulting